Now that my sewing room is mostly together I wanted to get back into Project Custom Clothes for my friend, Jamie. When I last posted about it in November I’d just tried to create my first bodycon dress and had failed spectacularly.

My biggest issue at that point was I needed to make sure that Addie conformed to Jamie’s body shape as best as I could get her. Jamie had sent me pictures of her dressed in some form-fitting clothes and then had sent those to me so that I could compare how they fit her versus how they fit Addie.

At this point there was a hiatus because I was trying to get through the holidays and then get through my bathroom closet and sewing room remodeling projects.

There was also a delay because I was nervous and hesitant. I knew that it was going to be a lot of work and fussing around to try to get Addie padded out just right. I worried that I wouldn’t be able to come close to what I needed, and then I worried that I had invested a lot of time and money into a project that would end up failing miserably. However, the Biltmore did not use the guy down the road to carve the goblins sitting on the roof. Instead they used craftsmen who had studied and lived stone carving all of their lives. At one point they really sucked at their craft, too. That’s the long way of saying that everybody begins from a point of zero ability and zero knowledge. So I squared my shoulders and went to work.

I’m glad I had the pictures and clothes from Jamie because the biggest change I had to make was in Addie’s shoulders. Jamie is a tiny and petite woman, but she has quite a set of shoulders and rib cage. (FYI… the following statement is a compliment) I think that she could have easily dressed like a Gibson Girl without having to add much cinch or padding to her corset.

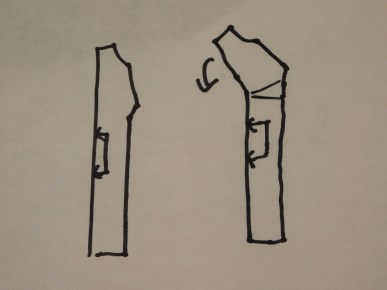

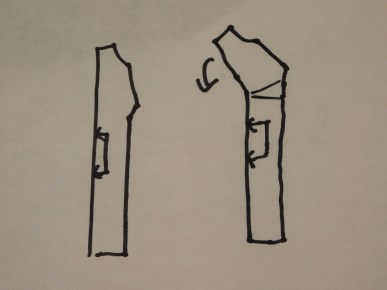

I’m not sure how much you will be able to see the differences, but I’ll post a Before shoulder padding and After:

This illustrates how the same dress (no adjustments had been made) will hang differently based on the shoulders. That’s the reason why most fitting instructions for dresses and tops have you start at the shoulders and work your way down. Often once you fix the shoulder issues some of the other problems will go away.

Feeling better about the fit of garments that I would be trying on Addie I decided to plunge into the bodycon dress. I didn’t go back to the red one, though. Instead I decided to use a pattern that was definitely for a very form-fitting dress. I used McCall’s M7999.

Instead of using numbered sizes, this one does the range of XS to XL, which makes sense since there is a lot of stretch to the fabrics you should be using. This time I chose the size that corresponded to Jamie’s measurements (mostly) and used a Polyester/Cotton/Lycra Interlock Knit. The only adjustment I made to the pattern was to create more of a scoop neck because I know there is NO WAY Jamie would be comfortable with such a high neckline (we think she must have been strangled in a previous life and now can’t stand anything even remotely constricting near her throat).

I was very pleased. I knew there would be some issues, but I didn’t feel that I had completely failed. From the front most of it looks good, except for the saddle bags at the hips. I told Jay that it looked like she was wearing the old riding pants with the poofy sides under the dress.

I was not stretching this at all. I had merely tugged it to see how much extra material was sitting in this area. It looked to be at least 2″ on each side. Then I turned Addie to look at the side.

This is definitely not a flattering fit from the side. Again, this is suppose to be a body conforming dress. That definitely wasn’t happening here, but when I turn her around to the back you will see why.

The shoulders seem to fit good, but there is all kinds of extra material swimming around her back (and a better view of the poofy pants at the hips). I grabbed my pins to see how much extra fabric I was dealing with in the back.

You can’t really tell, but I had almost 2″ of fabric pinned up to get the wrinkles out. What does this mean? This means that we need to do a sway back adjustment. To be honest, after seeing Jamie’s pictures, I realized that a sway back adjustment will be needed in any pattern that I use for dresses or tops. If you’ve never heard of this adjustment, let’s see if I can do an okay job of explaining it, using one of my very horrible drawings.

(I will explain more of this drawing later). Let’s pretend that the drawing on the left is of your “normal” person standing in profile. The big pattern companies design their patterns to fit these people. This is why so many sewers have to make adjustments to patterns in order to get the garments to fit their bodies. Well, if you stand especially tall (like we’re suppose to) with your shoulders squared and your bosom jutted out in front of you, this actually causes a curve to your figure and shortens the distance between your shoulders and lower back. The person on the left will have a much longer measurement (and require more material to span that distance) than the person on the right. I realize the drawing is a bit exaggerated, but hopefully you get the idea.

Before I did a sway back adjustment, though, I wanted to take the extra fabric out of the sides. I decided to do the adjustments one step at a time so that if something went completely wrong I would know exactly what caused it. I calculated approximately how much material I wanted to remove and then adjusted my pattern.

I actually thought that I would grade the pattern down, but after getting this far I realized that I would just remove the extra while keeping the same shape and wouldn’t worry about the pattern for the next size. Then I recut the fabric pieces (I’ve used basting stitches to sew them together so that I can easily remove it), and basted them back together. Let’s see how it looks after the width is removed.

I only removed width starting around the waist area, which is why the top still looks slightly baggy. But look how much better it sits at the hips! Let’s get a side profile comparison.

Look at the difference! I’ll admit that I might have taken off a little too much, but I can always add a smidgen back onto the pattern. Remember, this is not how it’s going to look on Jamie exactly, but it will be very close. Now let’s look at the back.

We definitely fixed the conforming issue at the hip. However, now the extra material on the back is REALLY noticeable. Also, I don’t think that I had done a good job smoothing out the back of the dress. Addie has a bodysuit on to keep all of her padding in place and it really likes to hold onto this fabric.

I am at the point where I definitely need to make the sway back adjustment. Most of my fitting books, though, only discuss how to adjust woven fabrics, garments with center seams, or garments with other seams. This is a bodycon dress so I only have the side seams to work with and everything that I’ve been reading assumes that you’ll have a back center seam. Let’s take a look at my drawing again so that you can see my quandry.

When you do a sway back adjustment you figure out how much material you need to remove at what spot and then pivot at the side to move the back down and create your new pattern line. Again, that makes sense because you want your side seam to remain the same length, but you want to remove a portion of the back area. I had to remove 2″ from the back of this dress. When I did the pivot like everything was saying, my pattern piece looked almost exactly like the one on the right. It had quite the sharp bend. You can’t put that on a center fold. So what do you do? You turn to the internet because obviously you aren’t the first person to have this issue.

I found a couple of blog posts that described the process of doing the pivot for the adjustment, and then you have to redraw the pattern piece in order to straighten out the back piece if you want it to be aligned on the center fold of your fabric. It requires a lot of drawing and monkeying around that I wasn’t looking forward to doing.

I dragged my feet and procrastinated. The pivoted pattern laid on my cutting table taunting me as I justified my delay with the excuse that I was doing more research. Then I stumbled across the most wonderful blog post in sewing history at a blog called Pattern.Scissors.Cloth. Not only does she do a WAY better job of explaining the sway back adjustment, but she also shows a much easier way of doing it based on her experience. Please go check it out if you have any interest in doing this type of adjustment because it will save you a TON of time!

I adjusted the pattern, recut the pieces of fabric and basted them back together. Let’s see the first (baggy) version versus the final adjusted version.

Not a huge difference from the front. Let’s look at the side, though.

What a difference! Yes, there are still some drag lines, but honestly I’m at the point where I need to send the muslin (my adjusting garment) to Jamie to have her try it on and see if some of those issues are resolved. I think she will fill out the top in different spots so the fabric will sit differently on her.

This is just a guess on my part based on the fact that when I pull the underarm up and out, the wrinkles mostly disappear. For good measure, let’s take a look at the back.

I was so happy with the results that I had to text a picture of it to Jay while he was at work. He knew that I had been struggling with the fit, so even if he didn’t quite understand what he was looking at he could completely understand my excitement.

There are certain things about Addie that I can’t adjust to exactly match Jamie, so that’s why I’m going to stop adjusting this particular muslin and send it to Jamie for some final fitting. I’m just excited that I actually have something to send Jamie to try on. Once I get this pattern just right I should be able to theoretically use it to make numerous dresses out of different stretch materials. I can lengthen the hem or add sleeves, but as long as I have the core part of the dress pattern perfected I shouldn’t have any issues.

I decided to use this adjusted pattern to fix the problems with the original bodycon dress that I had attempted, but that failed spectacularly. *sigh* Once again I fell into the barrel of thinking that I sucked and can’t do anything. Except, after doing more research it dawned on me what failed, so this weekend I’m going to take a second stab at it. If I can get a dress made out of Ponte knit (the red fabric) that fits almost as good as the gray fabric then I will be really happy. Wish me luck!